PRODUCTS

-

Boat Hoist Crane

- Yacht Hoisting Crane

-

RTG Crane

- Single Girder Rubber Tyre Crane

- Double Main Girder Tyre Gantry Crane

- Beam lancher

- Straddle Carrier

- Rubber Tyre Container Gantry Crane

-

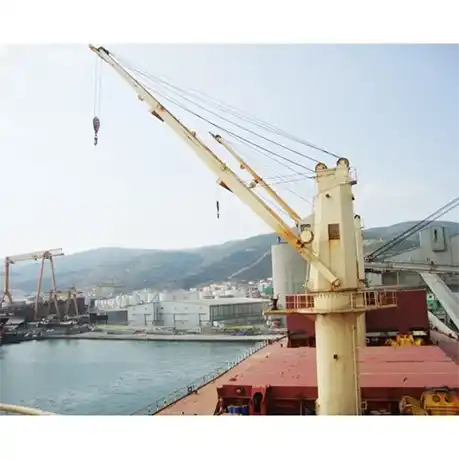

Marine Crane

- Marine Telescopic Boom Crane

- Marine Knuckle Boom Crane

- Marine Stiff Boom Crane

- Offshore Crane

- Marine Hatch Cover Gantry Crane

- Marine Cargo Deck Crane

-

RMG Crane

- Rail Mounted Container Gantry Crane

- Shipbuilding Gantry Crane

-

Portal Crane

- Single Jib Portal Crane

- Four Link Portal Crane

- Floating Dock Crane

-

General Industrial Crane

- Single Girder Overhead Crane

- Single Girder Gantry Crane

- Double Girder Overhead Crane

- Double Girder Gantry Crane

INDUSTRIES

- Manufacturing

- Marine

- Port

- Construction

- Energy

- Transport

- Metallurgical

- Electronics

- Logistics

- Mining

-

Four Link Portal CraneSUBMITDOWNLOAD

Four Link Portal CraneSUBMITDOWNLOAD -

Single Jib Portal CraneSUBMITDOWNLOAD

Single Jib Portal CraneSUBMITDOWNLOAD -

Floating Dock CraneSUBMITDOWNLOAD

Floating Dock CraneSUBMITDOWNLOAD